Finger joint

4.7 5 (1 Vote)1. Definition of Finger Joint Wood

Finger joint, also known as finger-jointed lumber or finger-joined wood, is an engineered wood product manufactured by joining small pieces of natural wood together using adhesive. These pieces are then pressed and bonded under specified temperature and pressure to create larger wood panels.

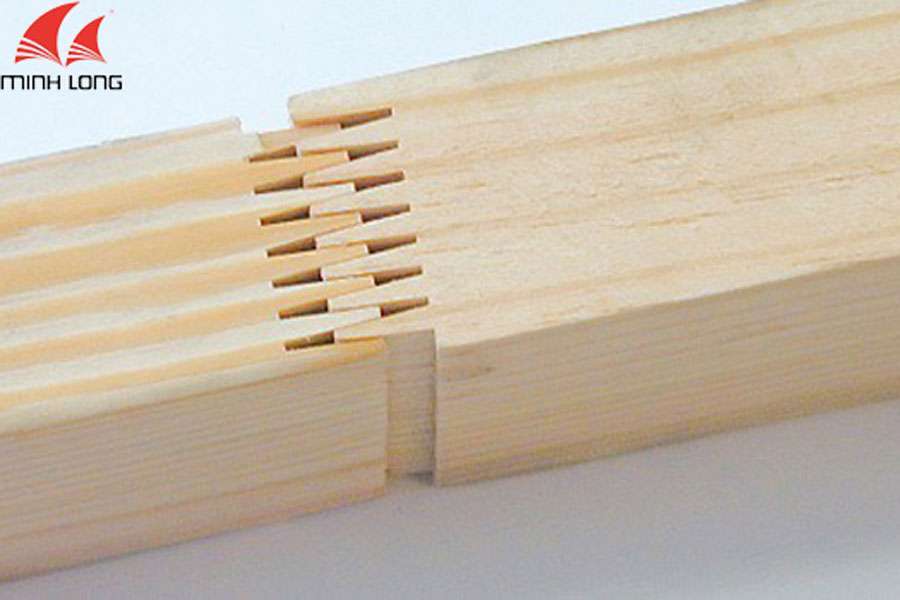

The individual wood pieces are connected using finger joints, which resemble interlocking fingers, hence the name "finger joint." The process of joining the wood pieces together creates large panels with strong bonds and high durability. Finger joint wood is often confused with box joints used in box or crate construction.

2.History of Formation and Development

Finger joint wood has been in existence for a long time, but its significant development occurred after 1970. Europe has the largest production of finger joint wood, followed by North and South America, and Asia. In Asia, Japan is the leading producer of finger joint wood, followed by South Korea and Indonesia.

3.Composition of Finger Joint Wood

Finger joint panels are essentially industrial-grade wood products that possess similar qualities to natural wood panels since they are made natural wood pieces. Common wood types used for finger joint wood production include rubberwood, pine, fir, and acacia, as well as non-standard wood species such as cornices various small workshops, small-diameter woods, and other salvageable woods not suitable for finished furniture.

The primary adhesives and additives used in finger joint wood production are Urea Formaldehyde (UF) adhesive, Phenol Formaldehyde (PF) adhesive, and Polyvinyl Acetate (PVAc) adhesive.

4. Production Process of Finger Joint Wood

The production process of finger joint wood includes the following steps:

Step 1: Wood Drying

The wood pieces need to undergo strict drying to remove components such as bark, resin, and sap the wood's interior. This process helps to prevent insect infestation, wood decay, and minimize wood shrinkage or expansion due to external conditions like weather and environment.

Step 2: Wood Cutting

The wood pieces are cut to the desired size and purpose of the product. Typically, the width of the wood pieces ranges 50 to 95mm, the length 200 to 500mm, and the thickness 10 to 40mm.

Next, the wood pieces are notched (finger-jointed) in two common formats: vertical finger joints and horizontal finger joints. Vertical finger joints provide sturdiness to the wood panel but leave visible interlocking lines on the surface. Horizontal finger joints, on the other hand, hide the joints, providing a more aesthetic appearance, but they may not offer the same structural integrity as vertical finger joints.

The wood pieces are also carefully selected to eliminate any uneven colors, knots, or splits. Finger joint wood is classified quality grades such as AA, AB, AC-AD, BC, CD, etc., based on their appearance and defects. Cụ thể:

-

AA Grade Finger Joint Wood:

- This grade features two beautiful and defect-free surfaces with relatively consistent color.

- Both surfaces have no defects accounting for at least 90% of the total area, with the remaining 10% possibly containing minor defects such as small black streaks or dead knots measuring less than 3mm in diameter.

-

AB Grade Finger Joint Wood:

- This grade has one beautiful surface with no defects and relatively uniform color.

- The other surface may have defects, including black streaks or dead knots with a diameter of up to 10mm.

-

AC – AD Grade Finger Joint Wood:

- This grade consists of one beautiful surface with no defects and relatively consistent color.

- The other surface may have defects, such as larger black spots, dead knots with a diameter greater than 10mm, or defects in the wood's core.

-

BC Grade Finger Joint Wood:

- This grade exhibits defects on both surfaces, with one surface (Surface B) having smaller defects compared to the other surface (Surface C).

- Surface C may have defects, including defects in the wood's core.

-

CD Grade Finger Joint Wood:

- This grade has defects on both surfaces, with more defects compared to the BC grade.

- The surface may also have some mold. This type is commonly used as a subfloor and requires surface treatment through sanding or filling.

- CD grade finger joint wood is suitable for subflooring or can be painted with low-gloss requirements or veneer overlay.

Step 3: Rough Planing

The wood is rough planed to reduce its roughness and prepare it for adhesive application and finger jointing.

Step 4: Adhesive Application and Finger Jointing

Adhesive is applied to the grooves and edges of the wood pieces. Subsequently, the pieces are finger jointed (either vertically or horizontally) and joined together to form large panels with standard dimensions of 1220x2440mm or custom sizes as required by manufacturers.

After joining, the panels are pressed on both the surface and the edges with standard pressure for approximately 12 hours to ensure a dense bond, allowing the adhesive to dry.

Step 5: Sanding and Surface Smoothing

After the pressing process, the panels are sent to sanding machines to smooth the surface to standard dimensions of 1220x2240mm or 1200x2400mm, depending on customer and manufacturer requirements.

Step 6: Quality Inspection

The finished panels are inspected for quality and minor finishing before being sent to the finished goods warehouse.

5. Advantages and Disadvantages of Finger Joint Wood

Finger joint wood inherits many advantages of natural wood, and it can effectively replace natural wood due to its physical durability, water resistance, and load-bearing capacity.

Finger joint wood panels have excellent load-bearing capabilities, making them suitable for various construction projects and homes. They are also widely used due to the abundant source of raw materials, sustainable use of plantation forests, and their expansion in the furniture industry.

Despite its notable advantages, finger joint wood may have aesthetic limitations, particularly with vertical finger joints. Typically, finger joint wood panels are not used directly on interior surfaces but are veneered or covered with High-Pressure Laminate (HPL) to enhance aesthetics and utility. As a result, the application of this type of wood for interior furniture in panel form is limited compared to other common industrial wood panels, such as particleboard, MDF, and plywood.

6. Applications

Finger joint wood is commonly used in construction and shipbuilding industries. It is also utilized for wall cladding, ceiling cladding, and various flat panel components.

In the construction industry, finger joint wood is used for structural beams and formwork panels for concrete. Additionally, it finds widespread use in interior design, furniture production, and as accessories for wooden windows and doors.

7. Get a quote

Finger joint wood has become a common industrial wood product in today's market and is produced by many reputable suppliers. The price of finished finger joint panels is higher than particleboard or MDF due to the basic raw materials being natural wood pieces, rather than wood chips or wood pulp used in other types of panels. Customers seeking pricing information for common industrial wood panels like particleboard, MDF, and plywood Gỗ Minh Long can contact the hotline 1900 636 668 for consultation and clarification of any questions.

AAdministratorsAdministrators

Welcome, honored guests. Please leave a comment, we will respond soon