Particle board

4.1 5 (1 Vote)1. What is Particle board?

Particle board, wood chip (also known as Okal board) is a wood-based product that is composed of wood chips, adhesives and other components (Parafin, hardener...) that are pressed under high temperature and high pressure.

2. History of Particle board

The history of chipboard (Okal wood) production and development is still relatively new. It originated in Germany. Himmelheber, an inventor and Luftwaffe fighter pilot, created chipboard in a factory in Bremen, Germany, in 1932. The original chipboards were created wood chips, shavings, and sawdust, which were then bound together using a specific adhesive.

However, the chipboard industry did not begin to flourish until after 1945. This business began in Germany and quickly extended to Switzerland, England, France, Belgium, the Netherlands, Austria, Italy, and Finland. Europe accounts for more than two-thirds of global chipboard production.

3. Composition of Particle board

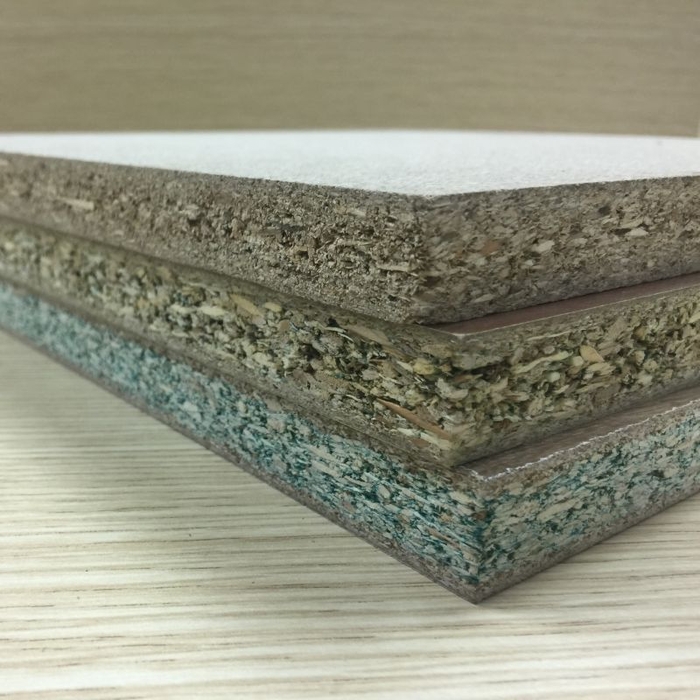

Normally, the composition of particle board contains around 80% wood, 9 - 10% Urea Formaldehyde (UF) glue, 7 - 10% water and less than 0.5% additional additives (Paraffin, hardener..). To strengthen the moisture resistance of the board, Melamine is commonly added UF glue (also known as MUF glue - Urea Formaldehyde modified with Melamine) (also known as MUF glue - Urea Formaldehyde modified with Melamine). To strengthen the fire resistance of boards, plaster and cement are occasionally added as binders.

Typically, production materials include wood, such as eucalyptus, acacia, or rubber, or wood waste generated during processing (cornboard, shavings, sawdust...). Plants that contain lignin and cellulose, such as rice straw, bagasse, cotton stalks, flax, or hemp, can be utilized in addition to wood.

4. Physical properties and general features

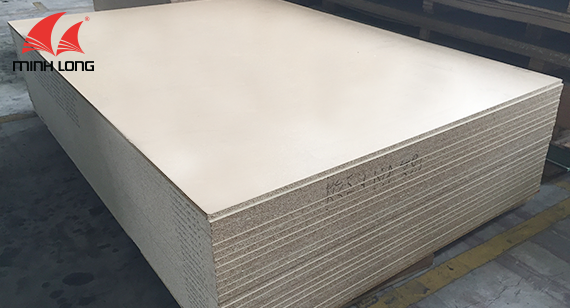

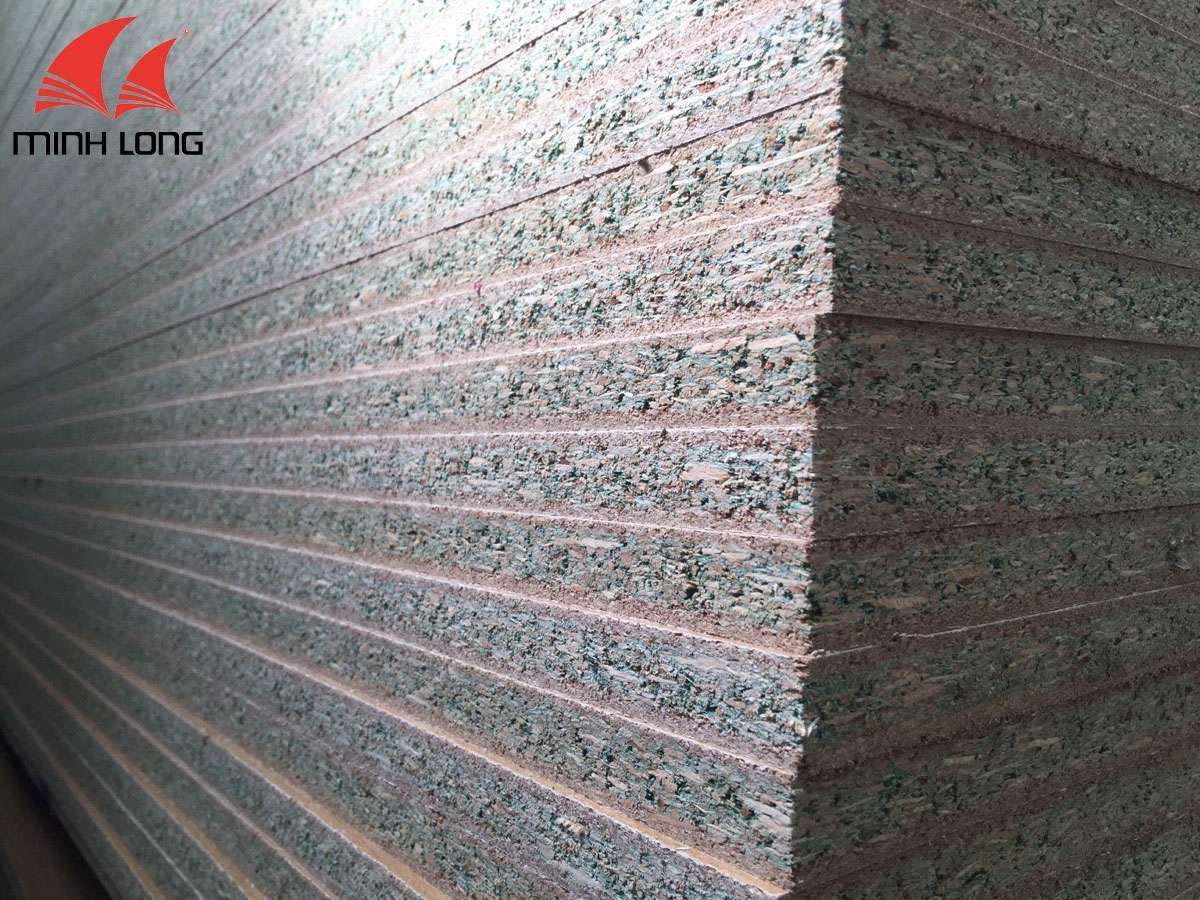

- Generally, chipboard has a distinct wood color (yellow, brown). Moisture-proof boards are often green, whereas fire-resistant boards are typically red.

- In sheet form, chipboard is considered stable and neutral. Boards have the ability to biodegrade over time. There is no scent in particle board.

- There is no scent in particle board.

- The typical density of particle board is 650-750 kg/m3.

- The most common chipboard dimensions are 1220 x 2440 and 1830 x 2440 (mm).

- Chipboard thicknesses commonly used: 17, 18, 25 (mm).

5. Production of Particle board

Under high temperature and pressure, wood chips, adhesives, and other ingredients (Paraffin, hardener...) are pressed. Production of particle board:

- The wood is first cut little fragments.

- After that, the wood chips are dried at a specific temperature.

- The wood chips are next sieved and sorted various sizes.

- These wood chips are combined with adhesives before being used in the shaping process.

- Planks are formed to meet thickness and density requirements.

- The boards are pre-pressed and trimmed to conventional lengths once they have been formed.

- The board is then pressed under high temperature and pressure in the next stage.

- After that, the board is trimmed to remove any edge imperfections.

- The final procedure is to polish the surface and check the board's surface quality.

6. Advantages of Particle board

- The price is more affordable as compared to MDF or plywood.

- The chipboard has a high hardness and mechanical strength due to the structure of wood chips.

- Good screw-holding.

- Because the surface of the chipboard is relatively flat, decorative materials such as Melamine or Laminate can be easily pressed on top.

7. Disadvantages of Particle board

- Chipboard has a lower load-carrying capacity when compared to other boards.

- Because of the structure of wood chips, the cutting edges are frequently damaged when cutting the board.

- Furniture built of chipboard has a shorter life span than other wood-based boards.

8. The price of Particle board

If you need to know the price of particle board, please contact Minh Long Wood right away to get the most recent updated chipboard and chipboard quotes.

9. Application of Particle board

Particle board is often continued to be covered with decorative surfaces for interior applications such as tables and chairs, beds, cabinets....In addition, Particle board are also used to make molds for concreting.

AAdministratorsAdministrators

Welcome, honored guests. Please leave a comment, we will respond soon