MDF

4.7 5 (1 Vote)Call the hotline at 1900.636.668 for the most recent MDF board quote.

1. MDF board definition

MDF (Medium density fiberboard), often known as medium density fiberboard, is a wood-based product whose major component is wood fiber (or wood pulp) manufactured soft and hardwood., adhesives, and certain other components (Paraffin, hardener...) are pressed under high temperature and pressure.

2. History of MDF

MDF has a relatively short track record of development. The first MDF factory was created in 1964 in New York (USA), and the industry has grown in various North American and European countries since 1990.

There were only three factories in the world with capacities ranging 39,000m3/year to 133,000m3/year prior to 1970.

However, by the year 2000, there were 291 factories globally, with the greatest manufacturing capacity reaching 340,000 m3/year. To meet market demand, industrialised nations have accelerated the development of MDF facilities, with a 15.5% yearly rise in output. In 1996, the globe produced 17.53 million m3, but by 2001, the entire global production of MDF board had risen to 29,056 million m3.

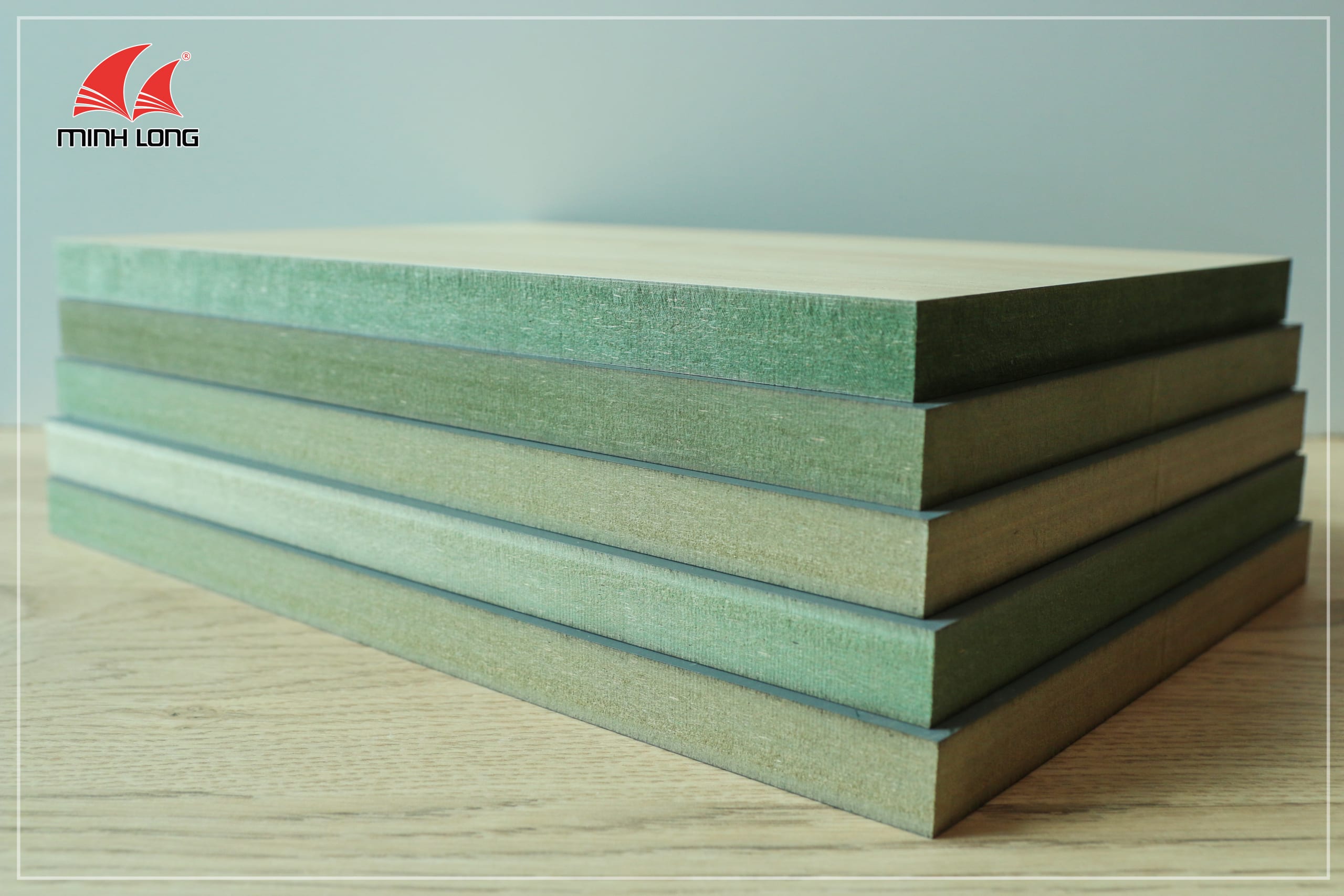

3. Structure of MDF board:

- MDF board is composed primarily of wood fiber (or wood pulp), glue, and a few other elements (Parafin, hardener...).

- MDF board is typically composed of approximately 75% wood, 11-14% Urea Formaldehyde (UF) glue, 6 - 10% water, and less than 1% other materials (Parafin, hardener...). Melamine resin or Phenolic & Polymeric Diphenylmethane Diisocyanate (PMDI) resin is added to the glue to generate moisture resistant MDF in high humidity settings.

- The wood fibers (or wood pulp) in MDF are primarily derived soft woods. Certain hardwood ingredients may be added to achieve the desired wood type, depending on the manufacturer's goal.

- Industrial plants (such as rubber, eucalyptus, acacia, pine, rag, oak, spruce), bagasse, wood waste, sawdust, or a blend of hardwood chips and soft wood chips are used to make MDF boards. In addition to the trunk's wood, the input materials can include branches, corn husks, pieces, and sawdust the sawing operation.

4. Physical features and general characteristics

- MDF wood typically has the natural color of wood (yellow, brown). Moisture-proof boards are typically blue, while fire-resistant boards are typically red.

- In panel form, MDF boards are considered stable and inert. Boards have the ability to biodegrade over time.

- MDF board is odorless.

- The average density of MDF board is 680 - 840 kg/m3.

- The most common MDF board dimensions are 1220 x 2440 and 1830 x 2440. (mm).

- Common MDF board thicknesses: 3, 5, 9, 12, 15, 17, 18, 25 (mm).

5. MDF board production

MDF board is made by crushing little wood fibers under high pressure and temperature with the help of adhesives and other materials. There are currently two MDF panel production processes: dry production and wet production.

a. Dry process

- First, glue and additives are sprayed dry wood pulp in a mixer and pre-dried

- After the glue has been drained, the fiber powder will be spread using a spreader and raked 2-3 layers, depending on the size and thickness of the board. These flooring are put through a heated press. The press executes pressing twice. During the initial pressing (preliminary pressing), each layer is pushed separately. On the second pressing, all of the layers are forced together.

- The heat mode is set to eliminate steam while gradually solidifying the glue.

- After pressing, the boards are transferred, trimmed, sanded, and graded.

b. Wet process

- The wood pulp is first misted with water to generate flakes. They are immediately scraped and placed on the press plate.

- They are then heat pressed to the initial thickness.

- Finally, the board is subjected to high-temperature steam rolling to compact the two sides and drain all the water.

6. Advantages of MDF

- No warping, shrinking and termites like natural wood.

- In general, MDF boards are less expensive than plywood or natural wood.

- Because MDF has a fairly consistent structure, the cutting edge does not chip when sawing.

- Since MDF board's surface is flat and smooth, it may be easily painted or laminated with other decorative surfaces such as Melamine or Laminate.

- Since the output is relatively steady and the processing time is short, it is appropriate for mass manufacturing of the same items, thereby saving money and lowering product costs.

- Because the surface can be much wider than real wood, it is easier to design and manufacture large-sized goods without the need for joining.

7. Disadvantages of MDF

- Regularly, MDF has a low water resistance. This drawback, however, can be mitigated by utilizing moisture-resistant MDF instead.

- Since MDF board has a low toughness, it is very simple to chip.

- Since MDF has a limited thickness, it is frequently essential to link multiple boards together to manufacture items with higher thickness.

- Unlike natural wood, it is not feasible to carve textures on the surface, but only to create colors and patterns by pressing decorative materials on top.

- Because Formaldehyde is included in low-quality MDF board, it might be harmful to the health of the producer or user.

8. Classification of MDF

MDF boards are divided three categories standard MDF (light yellow), moisture-resistant MDF (distinguished in the Vietnamese market by a green indicator), and fire-resistant MDF (with red indicator) . However, the two most popular forms of wood-based panel in furniture manufacturing are standard MDF and moisture-resistant MDF.

Moisture-resistant MDF is frequently used for high-humidity locations, which are classified three levels:

- LMR standard moisture-proof board (moisture-resistant active component accounts for 5-7% of the glue composition).

- HMR standard moisture-proof board (moisture-resistant active component accounts for 12-15% of the glue composition).

- HMR V313 standard moisture-proof board (moisture-resistant active component accounts for 21-24% of the glue composition).

Currently, Minh Long Wood offers HMR V313 panel with a higher moisture resistance rankings, meeting more strict standards for specific furniture goods, in addition to the HMR standard board with superior moisture resistance. Coastal places, humid northern climates, mountainous areas, and areas with large temperature changes are especially vulnerable. To satisfy this requirement, the board test must undergo an exceptionally stringent testing process that includes a three-step cycle that must be repeated three times within 21 to 28 days for the most accurate findings.

Minh Long Wood is one of the few suppliers of moisture-proof HMR V313 boards on 17mm MDF boards in 4x8 sizes. This is a common board size that is currently utilized in the manufacture and construction of residential, office, and restaurant furniture.

9. Application of MDF

Decorative surfaces (Melamine, Laminate...) are frequently pressed onto MDF for use in manufacturing and interior decorating, such as tables, chairs, beds, cabinets, shelves, doors, and so on.

See more MFC products here.

AAdministratorsAdministrators

Welcome, honored guests. Please leave a comment, we will respond soon